WP3 has been devoted to cast different composition alloys and check the improvement of their performance. In this case, pure metallic rare earth elements were used (as opposed to the metallic oxides and oxalates delivered by WP1).

Following a Design of Experiments, different alloys were casted, using a mix of compositions and different REE.

The characterization that has been done is explained next:

- Castability: in this regard, the composition of the alloys compared to the theorical composition was analyzed, and the different lengths of fluidity samples were measured to evaluate the fluidity index of each alloy. Finally the oxides presence was measured with K-mould samples.

- Mechanical properties were measured for sand casted samples under tension and compression, and then again for HPDC samples of the selected Remaghic alloy undersb static tension and creep. In creep the conclusions were that better mechanical properties were obtained at room temperatures, in comparison with an unmodified reference alloy. The results from the experimental creep tests showed an increase in the creep resistance of the new Remaghic alloy: the new developed alloy could be used for applications at 100ºC with a stress of 90 MPa and at 150ºC with a stress of 45 MPa.

The following table summarizes some of the most significant results and their comparison with reference alloys.

| Mechanical Properties | Reference Primary Mg | Reference alloyed Mg | Remaghic | |

| Ultimate Tensile Strength (MPa) | 225 | 245 | 230 | |

| Yield Strength (Mpa) | 130 | 142 | 156 | |

| Elongation % | 8% | 10% | 7.30% | |

- Corrosion is one of the most important issues that magnesium presents that can be solved with the addition of certain rare earth elements. In this regard, in a first test campaign salt mist tests according to DIN EN ISO 9227:2012-09 and ASTM B117-11:2011-11 have been performed using a salt spray chamber. 5 different alloys showed an improved performance in terms of weight loss over the reference Mg alloy.

Besides, corrosion in skydrol and coca cola was also tested, following the applicable standards.

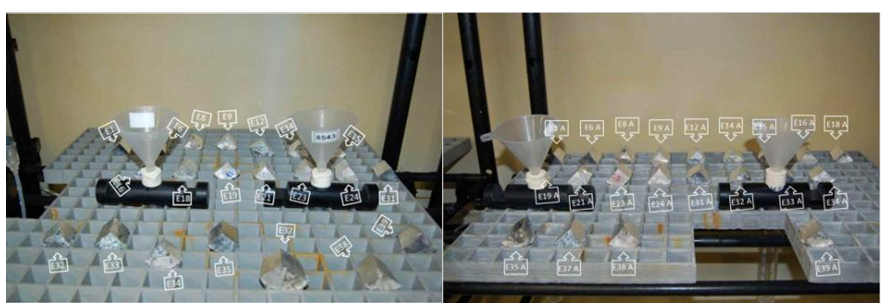

- Biomedical compatibility completed the characterization series. Permanent implants (e.g. titanium, stainless steel) have associated problems once bone has healed. Such problems include patient rejection or overall implant failure which in turn may result in a required second operation to remove the implant. The use of biodegradable materials which gradually degrade while enabling bone healing helps prevent the aforementioned problems. Among the candidate materials for biodegradable implants, Mg, in comparison to polymers, exhibits an improved biocompatibility behaviour and overall mechanical performance. However the degradation behaviour of Mg has so far limited its massive introduction in the market. Addition of REE to Mg can help to decrease degradation of Mg, and thus enhance the potential of Mg-based implants.

The results of these tests showed that two different alloys improved the reference Mg performance.

The results obtained in this WP are indeed promising: they show that according to the final desired need (better mechanical performance, corrosion, etc.) one or other mixtures of REE + Mg can be used. This WP has demonstrated that improved performance alloys can be obtained using secondary sources. The results reported in the deliverable and the conclusions from these characterizations are a promising result for future magnesium alloys development, and for the introduction of recycling schemes at magnesium foundries.

Recent Comments