The first step was the evaluation of the main industrial waste residues containing Rare Earth Elements (REEs). This objective has been achieved characterizing the considered input waste materials and identifying and quantifying the REE content. The outcome was a waste classification scheme according to the concentrations of the most interesting REE for the project (Y, Ce, La), taking into account the information about the presence of other REE. The preliminary analysis illustrated which industrial waste residues were suitable to proceed according to the project plan. The selected materials were collected and sent to the research partners for evaluation of different recovery techniques within the other WP1 tasks.

The second step was the assessment of each of the REE to achieve a low cost raw material. The balance between the demand by the economic markets and the natural abundance of the REE in ores is a major issue for REE suppliers. This is the so-called Balance Problem. The ideal situation is a perfect match between the demand and production of REEs, so that there are no surpluses of any of the REEs.

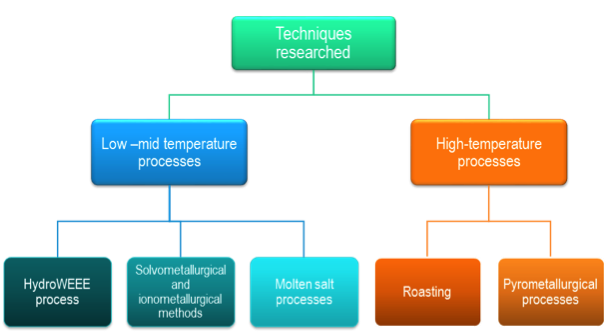

The final objective of WP1 was the optimization of the selected elements recovery strategies. The partners evaluated the results of all new processes (low, medium and high temperature processes) and their possible combination:

- Solvometallurgical and ionometallurgical methods (KU LEUVEN)

- Molten salts processes (FRAUNHOFER)

- Hydrometallurgical process (RELIGHT)

- Pyrometallurgical process (TECNALIA)

A process map was completed with this information in order to help the decision making mechanisms. WP1 partners are working in order to give a detailed evaluation of the different steps involved in the selected route and to provide data for the LCA and LCC models implementation and validation.

Recent Comments