Structure

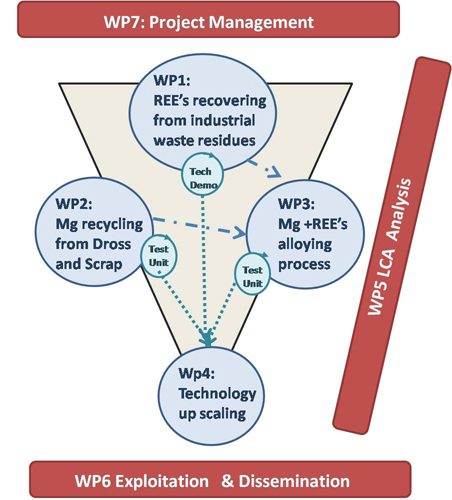

The REMAGHIC project is a 3 years project divided into 7 WP’s, the latter two being in charge of the project Exploitation, Dissemination and Communication activities (WP6), and the project Management (WP7)

Regarding the technical implementation of the project work plan, the project will build its foundations on the research of recovery processes of those rare earths that will be later used to be alloyed with magnesium. This work will be done in WP1, where the industrial collaboration of Relight and ITRB will be key to increase the TRL level that will be developed by the project research partners such as KU Leuven, Tecnalia, Fraunhofer and Relight as well. All the processes will be fed with the same residues (coming from Relight’s processes and acquired by ITRB to complete a full overview of possibilities) and compared in order to measure the cost of recovering each element and set it against its foreseen contribution to magnesium.

The same will be done with magnesium in WP2, where the recycling routes from magnesium dross & sludge and scrap will be researched in order to obtain secondary magnesium. This work package will also evaluate the recycling of magnesium alloys that already contain rare earths, measuring the rare earth content and the feasibility of recovering the dross and scrap coming from this Mg+REE alloy as well. The obtained secondary magnesium will need to be competitive in price and performance. Regarding the overall alloy price, LCCA analyses will be carried out later in WP5 to measure the progress so that every possible deviation from the project expected results can be solved in time. Regarding the material performance, different experimental tests will be carried out to verify the secondary magnesium based alloys can replace non recycled ones, including some sector specific tests as corrosion for the aeronautics industry and in vitro biocompatibility for the biomedical sector.

Both work packages WP1, and WP2 will feed WP3, where the alloying process will be studied. It is important to note here that though many rare earths can be alloyed with magnesium to modify its behaviour and microstructure, the contribution of each rare earth, the influence of the recycling process on the rare earth contribution, the alloying process parameters, and different element combinations need to be assessed quantitatively as much as qualitatively, which will be done with the decision matrix obtained in WP1 and completed with this WP tasks.

While many of the tasks in the aforementioned work packages will be carried out on a laboratory scale, this project aims to develop a demonstration system, proving the developed technologies work and operate on a pre-commercial scale. WP4 will deal with the magnesium recycling and Mg+REE alloying technology up scaling to industrial level; it will demonstrate the process efficiency and the obtaining of the final alloys on the industrial facilities of Grupo Antolín (magnesium recovery, alloying and sample manufacturing). It will identify final operational and manufacturing issues, making sure the technology can reach the market one year after the project ends.

The evaluation of the recovery processes efficiency and thus, the project success, will be carried out by the last work package in this description: WP5 will carry out Life Cycle and Cost Benefit Assessment, updating current LCA of each process to the advance posed by the project, validating the LCA models, and providing with important indicators on each of the strategies efficiency, environmental impact and cost.

WP1 - REE Recovery Processes from Industrial Waste Residues

Work package leader: RELIGHT

Objectives

-

Evaluation of the main industrial waste residues containing REE

-

Assessment of each of the REE elements to achieve a low cost raw material

-

Optimization and Combination of the selected elements recovery strategies

Tasks

Work in this work package has been divided into 4 tasks:

Task 1.1 Evaluation of the main industrial REE- containing waste residues

Task 1.2 Study of the balance problem

Task 1.3 Optimization techniques to recover the REE from the selected waste residue

Task 1.4 REE Recovery Technology demonstrator

WP2 - Magnesium Recycling from Dross and Scrap

Work package leader: CIDAUT

Objectives

-

Evaluate and optimize recycling routes from magnesium dross & sludge and scrap

-

Assess the evolution of the rare earth alloys in the recycling of Mg + REE alloys.

Tasks

Work in this work package has been divided into 3 tasks:

Task 2.1 Evaluation of the magnesium dross and scrap quality

Task 2.2 Recycling process optimization

Task 2.3 Magnesium recycling test unit

WP3 - Magnesium and Rare Earths Alloying Process Research

Work package leader: Grupo Antolín

Objectives

-

To select the rare earth elements for each use case

-

To develop and optimize the alloying processes for the recovered raw materials

-

To obtain and characterize new Mg+REE alloys for the selected Use Cases

Tasks

Work in this work package has been divided into 5 tasks:

Task 3.1 Selection of the most adequate Mg+REE for each Use Case

Task 3.2 Development of the alloying process from the recovered raw materials

Task 3.3 Test Unit for Mg+REE alloying process

Task 3.4 Characterisation of the MG+REE alloys

Task 3.5 New Mg+REE alloys material models for application design

WP4 - Technology Up Scaling and Industrialization

Work package leader: Grupo Antolín

Objectives

-

Implement the Magnesium Recovery and Alloying Processes to reach TRL7.

-

Assess the overall System Performance Demonstration

Tasks

Work in this work package has been divided into 2 tasks:

Task 4.1 Development of the alloying process from the recovered raw materials

Task 4.2 Overall System Performance

WP5 - Life Cycle Costing Analyses

Work package leader: Fraunhofer

Objectives

-

Quantify the economic and environmental benefits associated with the new process (recovering and allowing) by comparison with the current state of the art process from a life cycle perspective. The new technologies, intend to recover REE and Mg from industrial waste products using high- and/or low-mid- temperature processes. Additionally, the recovered REE and Mg will be used in a new process for produce Mg+REE alloying ingots.

-

The environmental assessment will be carried out following the standard ISO 14040 series. The specific objectives are:

-

Perform the data collection process for the economic and environmental assessment

-

Implement, refine and validate LCA analyses for the involved processes (recovery and alloying)

-

Perform an LCC analysis, efficiently and consistently combined with overall system LCA.

-

Define environmental and economic indicators and measurements for other WP decision making –Final LCA report presenting the environmental improvements of the new material and processes developed in this project beyond the current ones

Tasks

Work in this work package has been divided into 3 tasks:

Task 5.1 Rare Earth Recovery Life Cycle Assessment

Task 5.2 Magnesium Recycling Life Cycle Assessment

Task 5.3 Overall System Life Cycle Assessment

WP6 - Dissemination, Exploitation and Communication

Work package leader: ITRB

Objectives

-

To increase the awareness of the scientific research community towards the new possibilities in Mg recycling and REE recovery technologies

-

To increase the awareness of the industrial sectors involved in the project, mainly transport and biomedicine on the potential of the project results

-

To ensure the adequate protection of the Intellectual Property Rights

-

To ensure and effective communication is carried out continuously during the project to pave the way for the future products commercialisation

-

To refine the project’s business plan and plan the work for the post-project market introduction

Tasks

Work in this work package has been divided into 5 tasks:

Task 6.1 Dissemination

Task 6.2 Communication

Task 6.3 Exploitation

WP7 - Project Management

Work package leader: CIDAUT

Objectives

-

To ensure that the aims of the project are achieved with maximum impact

-

To plan and coordinate that the technical work is done in time

-

To manage the time, cost and resources allocation

-

To verify that the project deliverables are produced with the highest quality and in a timely fashion and duly reported to the EC